|

Direct Drive belt & system (DDK2 type) |

|

Because the sprocket is used for driving, slip and meandering do not occur. Since the rotation diameter at terminals is small, smooth load transfer is ensured. Because Kansai's unique Hardy-2 is used, the belt is characterized by little elongation

and high deformation resistance. |

|

|

|

|

|

|

|

|

|

|

|

|

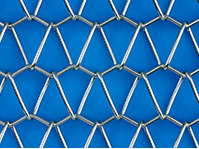

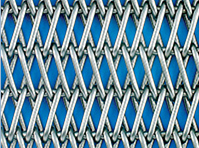

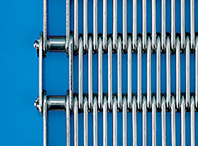

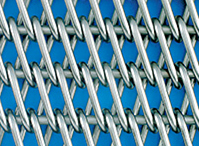

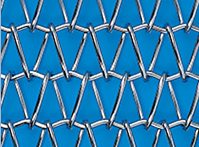

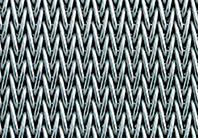

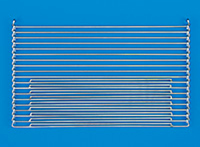

K2 type |

|

|

The left-wound and right-wound spiral are alternately arranged and jointed with the pre-crimped rods. |

|

|

|

|

|

|

|

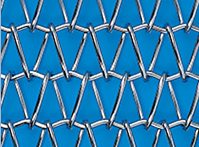

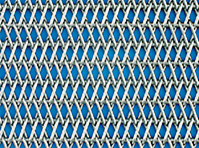

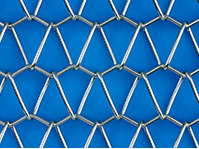

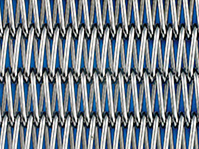

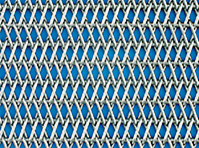

F2 type, A2 type |

|

|

|

|

F2 type |

A2 type |

|

|

|

The left-wound and right-wound spiral are alternately arranged and jointed with the straight rods.

If the rod pitch is less than two-fold spiral pitch, the belts are called A2.

If the rod pitch is equal to or greater than two-fold spiral pitch, the belts are called F2. |

|

|

|

|

|

|

|

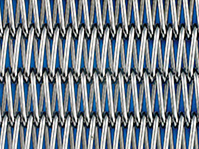

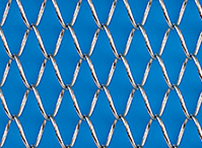

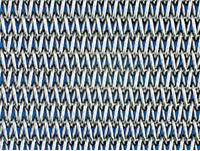

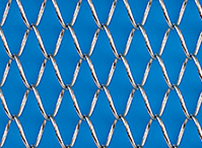

K2W type, A2W type |

|

|

|

|

K2W type |

A2W type |

|

|

|

K2W uses the K2 type spiral (double) whereas A2W uses the A2 type spiral (double).

K2W uses the pre-crimped rods to joint whereas A2W uses the straight rods. |

|

|

|

|

|

|

|

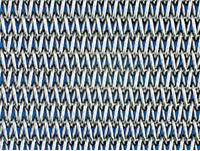

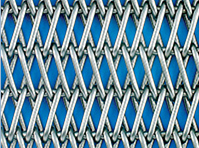

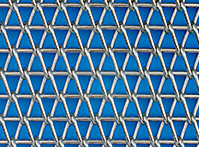

A4 type, A3 type |

|

|

|

|

A4 type |

A3 type |

|

|

|

The left-wound and right-wound spiral are fitted tightly together alternately and jointed with the straight rods.

A4 uses 4 rods for one spiral to joint. A3 uses 3 rods for one spiral to joint. |

|

|

|

|

|

|

|

S type |

|

|

Spirals wound in the same direction are arranged. |

|

|

|

|

|

|

|

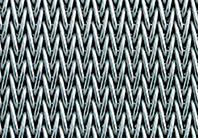

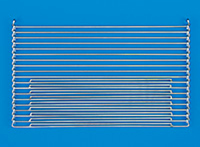

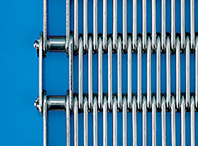

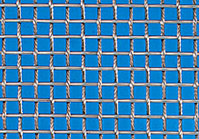

FW type (Flat Wire Belt) |

|

|

The flat wires are arranged in the form of lattice and jointed with

the straight rods.

The positive sprocket drive ensure stable running. |

|

|

|

|

|

|

|

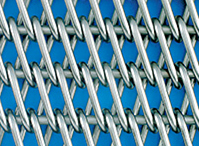

BL type (Flat Flex Belt) |

|

|

This belt is made by assembling the successively bend wires.

The sprocket drive ensure positive and stable running.

Easy washing is ensured. |

|

|

|

|

|

|

|

R2 type (Wire Ring Belt) |

|

|

Wires are formed into eye-links and jointed with rods. The belt has smooth surface, so that unstable products can be carried.

|

|

|

|

|

|

|

|

R1 type (Sani Grid Belt) |

|

|

Both ends of straight wire are bent, and the wires having bent ends are assembled.

These belts are most simple ones. Some version can be provided with the U bars preventing products falling. The material is generally SUS304 or high carbon steel wire.

The belts having wire dia. 3mm or less are called R1S. |

|

|

|

|

|

|

|

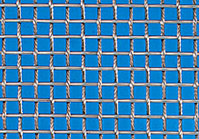

Woven Wire Rope Mesh |

|

|

Wire mesh woven by using wire rope for warps. It has flexibility.

This belt is mainly used for belt filter and dryer. |

|

|

|

|

|

|

|

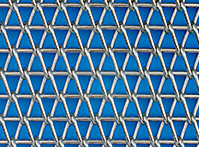

RRtype, RRWtype |

|

|

|

|

RR type |

RRW type |

|

|

|

These belts are used for heat treatment of metal products.

The spirals of the same direction are arranged, and the rods are passed through the spiral intersections. |

|

|

|

|

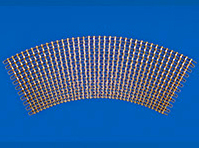

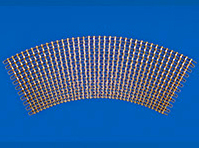

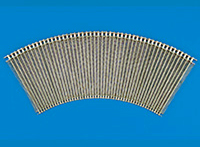

Curve Conveyor Belts |

|

|

|

|

CR1 type |

CFW type |

|

|

|

|

|

|

CBL type |

CCF2(CCSP) type |

|

|

|

The curve conveyor us used for line connection or direction change.

The sprocket drive ensures reliable and stable running. |

|

|

|

|

|

|

|

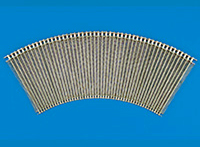

LR, LF2 type (for spiral tower) |

|

|

|

|

|

|

The LR type uses a combination of especially developed link and straight rod,

whereas the LF2 type uses combination with spiral mesh.

Turning inside radius is belt width x 2.0 for standard rod pitch 27.4.

One belt can used for both straight running and curve to the right and left.

Belt edges are finished to have consistent smooth surface. |

|

|

|

|

|

|

|

SD Belt System |

|

|

SD belt system with single row teeth sprockets is available.

Sprocket material is SUS303 and special specifications can be made.

This is good for replacing friction roller system with same size sprocket as existing drive roller. |

|

|

|