|

Sintered Woven Wire Mesh |

|

With our own sintering technology, different wire meshes are combined to form layers. All wires are fused to each other, so do not dislocate even under high pressure. The apertures in each layer are divided by the next layer, promising even finer and more uniform filtration. |

|

Sintered woven wire mesh include PORMET, PORFLO and BONMESH, differing in the component wire meshes, number of layers, the sintering method and pressures applied. |

POREMET |

|

Using a Dutch woven wire mesh in the 4th and 5th layers for reinforcement makes POREMET the most pressure-resistant in our line up. As this is surface filter medium, backwash cleaning is easy. |

|

Lamination Structure of POREMET |

.jpg) |

BONMESH |

|

Custom-made filters. Available in any number of layers and any type of wire mesh. Typical application is strainer. BONMESH strainer has integrated structure by sintering between meshes and perforated plate. BONMESH strainer is suitable for food processes (HACCP) and pharmaceutical industries (GMP), because of the sanitary structure and no impurity.

|

|

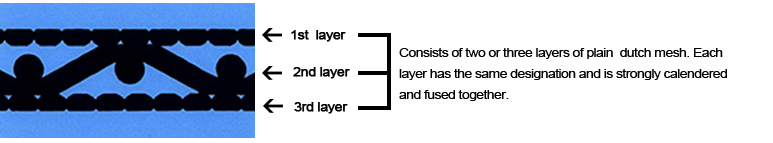

POREFLO |

|

|

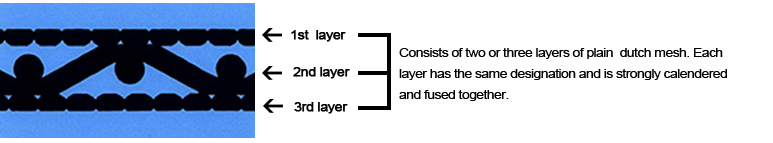

Porous plate made of sintered wire mesh which is heavily calendared.

Suitable for powder transportation, drying, flow rectification and uniform air output.

Pressure resistance is nearly equal to that of that of POREMET.

Available in two-layer and three-layer types. No.1 -No.12 represent the pressure drop from high to low,

No.1 having the highest resistance. Other specifications and Directional type are also available upon request. |

Lamination Structure of POREFLO |

|

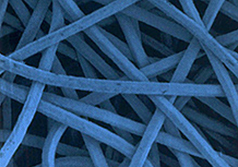

BEKIPOR® (Sintered Metal Fiber Web) |

|

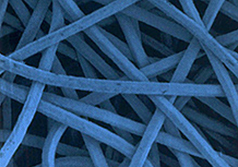

BEKIPOR® is non-woven sintered medium of ultra-fine metal fibers.

Depth filter medium.

The high porosity makes pressure drop low. High dirt holding capacity permits long

on-stream life.

A three-dimensional web of loose fibers in a non-woven labyrinth structure.

Holds not contaminant but gel as well.

|

|

|

In the flow direction from the coarser fiber side marked ''FLOW IN'',

longer on-stream life is expected. Flow from the finer fiber side produces

a particulate cake on the upstream surface of them medium in both backwash

(liquid filtration) and plus jet (gas filtration) applications. |

|

|

|

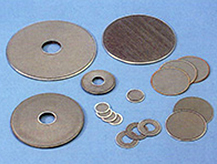

BEKIPOR® can be processed into various shapes including disk, candle, or pleated candle (except fro DL4), etc.

|

.jpg)