|

|

|

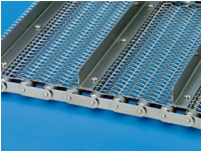

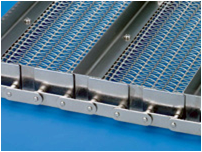

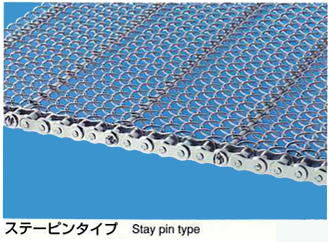

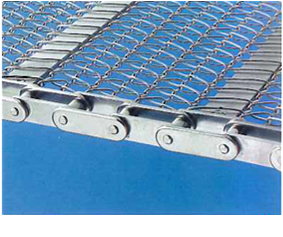

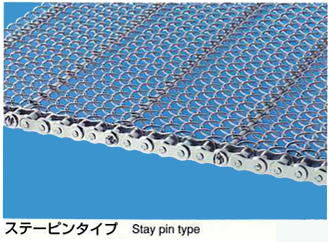

These belts are made by fitting chains to both side of ordinary wire conveyor belt. The belt and chain are synchronized through stays (cross supports).

Advantages

Because chain is drive by sprocket, meandering does not occur.

Various types of chain can be applied by adjusting belt pitch.

It is easy to attach side guard and product stopper in combination with chain and stay.

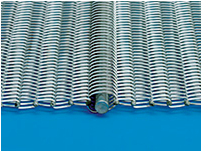

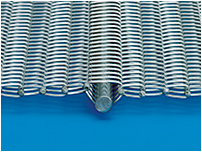

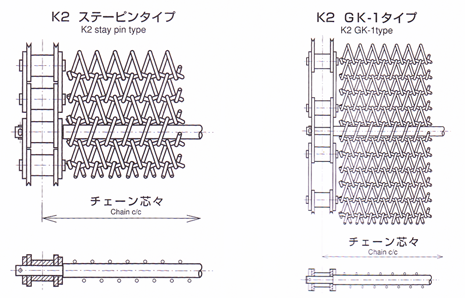

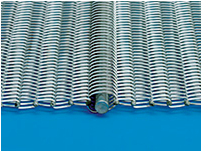

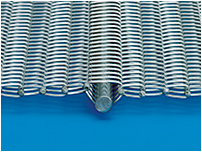

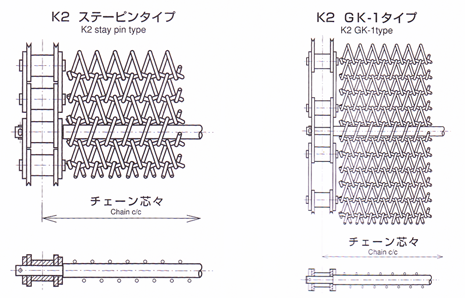

1. Type of stay / Stay pin type

The step-cut round rod (stay pin) is fitted to chain at both sides, and the thickness of spiral is adjusted so that the round rod passed inside the spiral.

|

|

|

|

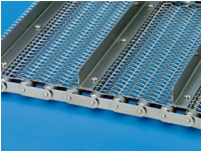

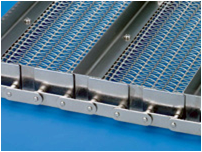

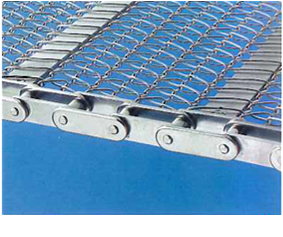

2. Attachment type

- Flat bar type

Chain with attachment is used. Flat bar is fitted to attachment at both sides, The flat bar is passed inside the spiral (as with stay pin type) or the belt is put on the flat bar. Spacer must be provided between the attachments and the flat bar so that the belt is located in the chain center.

- Angle channel type

This type is used to prevent deflection in case chain c/c is wide but support rail can not be installed. The same installation procedure as that applied to the flat bar is applied.

- Pipe type

Similar to angle type. With pipe type, however, it is necessary to crush pipe ends so as to fit to the attachment. If EP type chain is used, the same assembling procedure as that |

With Large Spiral

Attachment type

|

.png)

|

|

|

|

Constant Thickness |

With Large Spiral |

With Triangular Spiral |

Applicable belts

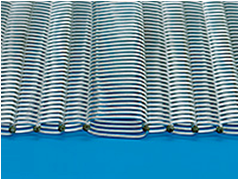

It is possible to fit to belts of almost all types, including woven wire rope mesh type.

Selection of wire conveyor belt with chain

1. Belt selection

Select the belt type, wire diameter and pitch according to type, shape, size, and weight of products.

2. Selection of chain and support

Select the chain and stay according to product conditions, belt width, length, speed, machine layout, etc.

|

|

|

With angle product stopper |

With slide guard, angle product stopper |

.png)