|

Advantages

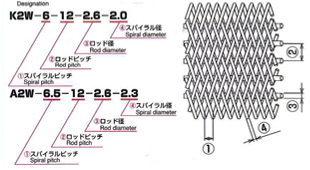

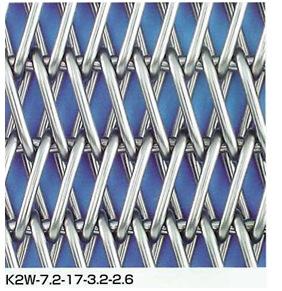

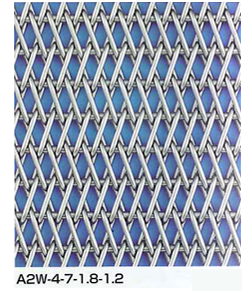

K2W, A2W Type (Double Balanced Belt)

K2 Type

A4, A3 Type

K2W, A2W Type

F2, A2 Type

S Type

Chain Driven Belt

RR, RRW Type

K2W uses the K2 type spiral (double) whereas A2W uses the A2 type spiral (double). K2W uses the pre-crimped rods to joint whereas A2W uses the straight rods.

K2W uses the K2 type spiral (double) whereas A2W uses the A2 type spiral (double). K2W uses the pre-crimped rods to joint whereas A2W uses the straight rods.

The allowable tension is high, so that heavy load can be carried.

The belts can be used at high temperature.

Having the fine mesh, the belts can be used for transportation of small items.

Typical specification of K2W (nominal size)

Typical specification of A2W (nominal size)

Specification

Weight (kg/m2)

Specification

Weight (kg/m2)

K2W 15 - 30 - 6.0 - 5.0

40.6

A2W 9.5 - 16 - 3.2 - 3.2

27.1

K2W 12.5 - 35 - 5.0 - 4.0

26.8

A2W 8 - 14 - 3.2 - 2.6

22.7

K2W 10 - 22 - 4.0 - 3.4

26.5

A2W 7 - 15 - 3.0 - 2.6

23.3

K2W 7.5 - 26 - 3.4 - 2.6

18.2

A2W 6.5 - 12 - 2.6 - 2.3

20.8

K2W 8 - 17 - 3.4 - 2.6

20.6

A2W 5.5 - 6.5 - 1.6 - 1.6

13.6

K2W 8 - 15 - 3.2 - 2.6

21.2

A2W 4 - 7 - 1.8 - 1.2

10.7

K2W 9 - 15 - 3.0 - 2.6

18.9

A2W 3.5 - 4 - 1.2 - 0.8

6.7

K2W 9 - 13 - 2.6 - 2.0

12.3

K2W 6 - 12 - 2.6 - 2.0

17.0

K2W 5 - 10 - 2.0 - 1.8

15.2

K2W 5 - 7 - 1.6 - 1.6

13.4

Technical Terms: - Edge Treatment

- Belt Endless

- Engineering